Manufacturing Options

- Isostatic pressing

- Die Pressing

- Hop Pressed / HIP

Advanced Finishing Services

-

Precision grinding and lapping

-

CNC machine shop

-

Engineering design and support

-

Complex cleanroom assemblies

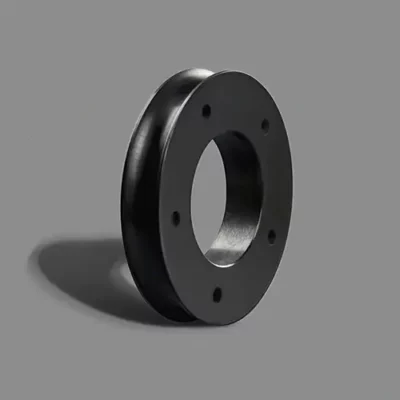

Silicon Nitride (Si3N4) ceramics is superior to other materials due to its thermal shock resistance. It does not deteriorate at high temperatures, so it’s used for automotive engines and parts for gas turbines, including the turbocharger rotor.

Ortech offers a complete family of Silicon Nitride materials. These materials have the following key characteristics: No adhesive wear against steel, Twice as hard as tool steel, Good chemical resistance and 60% less weight than steel.

Ortech provides state-of-the-art technical Silicon Nitride (Si3N4) manufacturing by the most cost-effective processes. Ortech maintains efficient manufacturing facilities that support quick-turn prototype development and high volume production.

| Sintered Silicon Nitride | |||

|---|---|---|---|

| Density g/cm3 | 3.20 | ||

| Crystal Size Average Microns | – | ||

| Water Absorption % | 0 | ||

| Gas Permeability – | 0 | ||

| Color – | Gray | ||

| Flexural Strength (MOR) 20° C MPa (psi x 103) | 900 | ||

| Elastic Modulus 20° C GPa (psi x 106) | 315 | ||

| Poisson’s Ratio 20° C – | – | ||

| Compressive Strength 20° C MPa (psi x 103) | 2500 | ||

| Hardness Rockwell R45N | – | ||

| Tensile Strength 25° C MPa (psi x 103) | – | ||

| Fracture Toughness K(I c) MPam1/2 | 7.5 | ||

| Thermal Conductivity 20° C W/m K | 19 | ||

| Coefficient of Thermal Expansion 25-1000° C 1X 10-6/°C | 3.1 | ||

| Specific Heat 100° C J/kg*K | 800 | ||

| Thermal Shock Resistance Δ Tc °C | – | ||

| Dielectric Strength 6.35mm ac-kV/mm (ac V/mil) | 15 | ||

| Dielectric Constant 1 MHz 25° C | – | ||

| Dielectric Loss (tan delta) 1 MHz 25° C | – | ||

| Volume Resistivity 25° C ohm-cm | 10 10 | ||

| Volume Resistivity 500° C ohm-cm | – | ||

| Volume Resistivity 1000° C ohm-cm | – | ||

| Maximum Use Temperature | 1400 C |